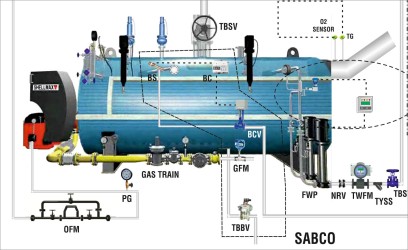

Surface Auto Blowdown Control System (SABCO)

SABCO – Surface Auto Blowdown Control System is a smart and energy-efficient solution designed for automatic boiler blowdown. It helps maintain the Total Dissolved Solids (TDS) at desired levels by accurately controlling the discharge of water from the steam-to-water interface in the boiler. This not only enhances boiler performance and safety but also reduces energy loss and operational costs.

Product Features of SABCO

- Accurate TDS Control: Automatically detects and removes excess TDS as it forms, ensuring optimal boiler water quality.

- Real-Time Conductivity Monitoring: Advanced sensors measure and control conductivity continuously, preventing unnecessary water wastage and energy loss.

- Enhanced Boiler Life: Reduces scaling and deposits, protecting boiler tubes and pressure vessels from damage.

- Non-Clogging Sensor Design: Prevents sludge buildup on sensors, ensuring long-term accuracy and minimal maintenance.

- High Durability Components: Stellited internals in valves protect against erosion caused by high-velocity water discharge.

- High-Temperature Blowdown Capability: Equipped with specially designed angle-type electric actuated valves with stellited seats and plugs for handling flashing conditions.

- Industrial Grade Electrodes: Uses stainless steel conductivity electrodes with Teflon insulation for precise and durable performance.

Benefits of Using SABCO

- Reduces boiler blowdown frequency and conserves valuable boiler water and heat.

- Maintains consistent boiler efficiency and enhances operational safety.

- Minimizes downtime and reduces maintenance costs.

- Increases boiler life and performance with precise and reliable TDS control.

- Ideal for high-pressure and high-temperature industrial boiler systems.

Applications

- Power Plants

- Chemical and Petrochemical Industries

- Textile and Dyeing Units

- Paper and Pulp Industries

- Pharmaceutical Manufacturing

- Food and Beverage Processing

- Sugar Mills

- Hospitals and Large Buildings