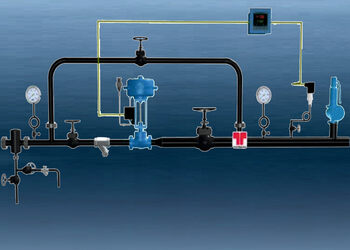

Pressure Reducing Stations (PRS)

PRS with Control Valve

Thermax Pressure Reducing Station (TPRS) is a prefabricated, ready-to-assemble module comprising PID-based control valve, isolation valves, pipes, and fittings. It is designed to reduce steam pressure to desired conditions for industrial processes.

Key Features

- Designed as per best steam engineering practices

- Safety valve sized for full discharge capacity

- Specially designed flow divider ensures low noise

- Rugged, long-lasting design

- Operates even in hazardous environments

- Consistent performance under low flow conditions

- Quick response to pressure changes

- Ready-to-install, minimizing installation time

- Low maintenance and user-friendly

- Available in IBR and non-IBR versions

PRS with Direct Acting Valve

Thermax Pressure Reducing Station (TPRS) with Direct Acting Valve is a pre-assembled module featuring a Direct Acting Pressure Regulating Valve, isolation valves, and associated fittings, designed to optimize steam systems safely and efficiently.

Key Features

- Engineered for superior pressure control performance

- Integrated safety valve for maximum protection

- Special flow divider ensures low noise levels

- Rugged, durable construction

- Non-electrical operation — safe in hazardous areas

- Reliable under low steam flow conditions

- Rapid pressure response for stability

- Plug-and-play installation

- Maintenance-free design

- Available in IBR and non-IBR options

Applications

- Steam pressure control in process industries

- Textile, pharmaceutical, and food industries

- Hazardous and non-hazardous area applications

- Retrofitting existing steam systems

Benefits

- Enhances energy efficiency and reduces waste

- Improves safety and extends equipment life

- Reduces noise, maintenance, and downtime

- Maintains consistent output pressure