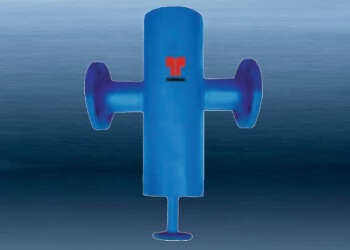

Moisture Separator – Enhance Steam Quality and Equipment Efficiency

A Moisture Separator is an essential device used in steam lines to remove suspended water particles. By delivering dry steam to equipment, moisture separators enhance operational efficiency, reduce maintenance, and protect valuable process equipment from moisture-related damage.

Key Features of Moisture Separators

- High-efficiency moisture removal with internal baffle plates and profiles.

- Supplies superior quality dry steam, boosting heat transfer and equipment efficiency.

- Durable construction with fabricated or cast steel designs.

- Standard flanged connections (ASME B16.5 #150/#300) for easy integration.

- Multiple sizes and materials available to meet different process needs.

Benefits of Using Moisture Separators

- Improves energy efficiency and reduces operational costs.

- Protects equipment from corrosion, erosion, and water hammer.

- Minimizes downtime by reducing equipment failures and maintenance.

- Enhances product quality with consistent, dry steam supply.

Applications of Moisture Separators

- Steam distribution systems

- Boilers and heat exchangers

- Food and beverage industries

- Petrochemical and chemical plants

- Pharmaceutical manufacturing

- Textile and paper industries

- Power plants and the energy sector

Specifications

- Material: Carbon Steel / Stainless Steel / Cast Steel

- Connection Type: Flanged (ASME B16.5 #150/#300)

- Design: Fabricated or Cast Steel versions

- Operating Pressure: Suitable for low and high-pressure applications

- Sizes: Customized sizes available upon request